Innovation in EV Battery Pack Sealing Technology

Automated Innovation in EV Battery Pack Sealing Technology

High-Viscosity Butyl Solutions

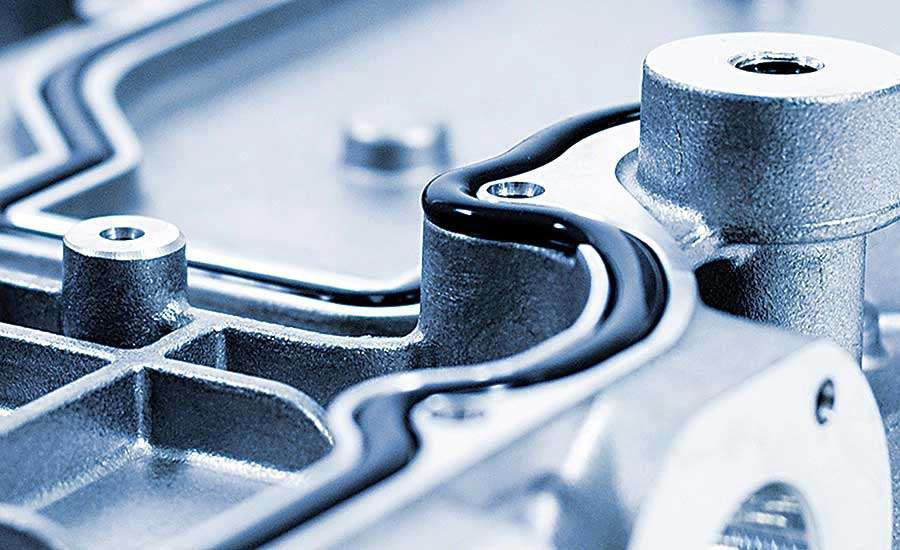

As the global electric vehicle (EV) industry accelerates its growth, the battery pack, serving as the core component of EVs, has seen its safety and production efficiency become the focus of manufacturers. To meet strict waterproof ratings from IP67 to IP69 as well as flame retardancy requirements, the battery pack sealing process is crucial.

This article explores how Nordson utilizes a high-viscosity butyl rubber automated dispensing system to provide battery manufacturers with an innovative "Dispense-and-Mate," fast-curing, and semi-serviceable sealing solution, thereby significantly increasing throughput and reducing total cost of ownership.

Market Drivers & Demands

Driven by environmental protection, cost optimization, and smart driving technologies, automakers are racing to invest resources to gain technological advantages. The market demand for battery packs goes beyond just energy density, emphasizing:

Safety: Must possess excellent watertightness and flame retardancy.

Low Cost & High Efficiency: Reducing unit costs through large-scale automated production.

Serviceability: As battery designs evolve, gaskets with "Semi-serviceable" characteristics are becoming a new trend, allowing for rework or disassembly when necessary.

Bottlenecks of Traditional Sealing Processes

Currently, common alternatives on the market (such as 2K Foam, Penguin Foam, or Dyna Foam) face numerous challenges in practical application:

Excessive Curing Time: Typically requires 4 to 14 hours to fully cure, or necessitates additional ovens or UV equipment to accelerate curing, which not only takes up factory floor space but also increases energy consumption.

Unstable Process: The mixing ratio of two-component (2K) chemical foams is difficult to control perfectly, leading to inconsistent foam appearance and performance; furthermore, insufficient closed cell content (<90%) may result in failure to pass IP rating tests.

Difficult Maintenance: Some materials cannot be disassembled after curing, failing to meet the market demand for semi-serviceability.

Innovative Solution

The high-viscosity butyl solution proposed by Nordson utilizes the physical properties of the material itself combined with precise fluid control technology to solve the aforementioned pain points.

Core Technology: Dispense-and-Mate

Unlike chemically reactive adhesives that require long waiting times for curing, high-viscosity butyl allows for the immediate mating and assembly of top and bottom covers after dispensing. This single-pass application method eliminates waiting time, achieving true Just-In-Time (JIT) production.

Application Scenarios & Equipment Configuration

This application is suitable for sealing between E-coated aluminum or steel trays and lids. To handle butyl rubber with viscosity as high as 1,000,000+ cps and ensure a dispensing path of over 2 meters without breaks or bubbles, we recommend the following configuration:

VD200 HP/Butyl System: A supply system designed specifically for high-viscosity materials to ensure stable output.

ProMeter GMG Gun: Adopts gear metering technology to record and verify dispensing volume in real-time, ensuring every bead meets specifications.

Pump Station: Provides a continuous and stable pressure source.

Benefit Analysis

Adopting Nordson's butyl sealing solution can bring multiple competitive advantages to battery manufacturers:

Production Efficiency & Quality

Increased Throughput: Since no oven baking or waiting for curing is required, the production cycle is significantly shortened.

Quality Assurance: The system ensures continuous dispensing without bubbles or breaks, easily passing IP67-IP69 watertightness tests.

Real-time Monitoring: Dispensed volume is verified and recorded in real-time, meeting automotive-grade traceability requirements.

Flexibility & Cost

Semi-Serviceable: Butyl gaskets allow for disassembly and rework when needed, which is impossible with traditional hardening adhesives.

Flame Retardant Options: Materials with flame retardant (FR) formulations can be selected to further enhance battery pack safety.

Low Maintenance Costs: Compared to complex 2K systems, the daily preventive maintenance for the single-component butyl rubber system is minimal, reducing downtime risk.

Comparison Item | Nordson Butyl Solution | Traditional 2K / Foam Solutions |

Curing Time | Instant (No waiting) | Slow (Requires 4-14 hours or oven) |

Process Steps | Single pass (Dispense and mate) | Complex (Requires mixing, foaming, waiting) |

IP Protection Rating | High (Easily passes IP67/69) | Higher Risk (Closed cell issues) |

Equipment Maintenance | Low | High (Mixing tubes clog easily) |

In the manufacturing of EV battery packs, the sealing process is the final line of defense for ensuring battery life and safety. Nordson's high-viscosity butyl solution, with its unique characteristics of "fast curing," "reworkability," and "full automation," enhances whole-plant production efficiency and product competitiveness.